Revolutionary Battery Technology Partnership Forms Between Zeon and SiAT

Have you ever wished your phone or electric car battery could charge faster and last longer? A major new partnership between two companies could make this possible sooner than you might think. Zeon Corporation and Sino Applied Technology (SiAT) have joined forces to revolutionize battery technology using tiny carbon tubes.

According to BusinessWire, this partnership aims to dramatically increase production of special materials that make batteries work better, with Zeon investing $20 million to help SiAT grow.

What Are These Special Carbon Tubes?

The special materials at the heart of this partnership are called single-walled carbon nanotubes (SWCNTs). These are incredibly tiny tubes made of carbon atoms – so small that you would need to line up thousands of them to match the width of a human hair.

.png) Think of them as microscopic straws that electricity loves to flow through. Unlike traditional materials used in batteries, these tiny tubes conduct electricity extremely well, are very strong, and don’t break down easily when exposed to chemicals.

Think of them as microscopic straws that electricity loves to flow through. Unlike traditional materials used in batteries, these tiny tubes conduct electricity extremely well, are very strong, and don’t break down easily when exposed to chemicals.

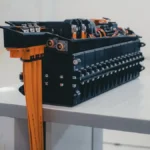

These carbon tubes are mixed into a special paste that gets applied to battery parts. This paste creates better pathways for electricity to move through the battery, similar to how a highway allows cars to travel faster than a bumpy dirt road. The companies have developed two types of this paste: LSC2102 (which uses a chemical solvent) and LSC1101 (which uses water).

Why This Partnership Matters

Making these tiny carbon tubes in large quantities has been extremely difficult until now. Zeon brings to the partnership a special method called Super Growth technology, which uses a process called Chemical Vapor Deposition (CVD) to grow these tubes much faster and better than previous methods.

SiAT contributes its expertise in solving another major problem: getting these tiny tubes to mix evenly in paste instead of clumping together. When carbon nanotubes clump together, they don’t work well in batteries. Think of it like trying to mix chocolate powder into milk – if it all clumps in one spot, you don’t get chocolate milk throughout your glass.

- Production challenge: Making carbon nanotubes requires extremely high temperatures and precise control. Zeon’s Super Growth method has solved this problem by making the process over 1,000 times more productive than older methods.

- Mixing challenge: Carbon nanotubes naturally stick together, making them difficult to spread evenly throughout battery materials. SiAT has developed special techniques to keep them separated and evenly distributed.

- Quality improvement: The partnership creates carbon nanotubes with better purity and more consistent size, which means they perform more reliably in batteries.

How These Improved Batteries Will Benefit You

When these carbon nanotube pastes are used in lithium-ion batteries, they create several important improvements that you might notice in your devices. First, batteries can charge and discharge faster, meaning less time waiting for your phone or electric car to charge. Second, the batteries last longer because the carbon nanotubes help hold everything together even as the battery components expand and contract during use.

This is especially important for newer battery designs that use silicon materials, which tend to swell and shrink dramatically during charging cycles. The carbon nanotubes act like a flexible scaffold that keeps everything working properly despite these changes in size.

| Battery Improvement | What It Means For You |

|---|---|

| Better electrical conductivity | Your devices could charge significantly faster than they do now, potentially cutting charging time by a large amount. This improvement comes from electricity flowing more efficiently through the battery. |

| Enhanced mechanical stability | Your battery would last many more charging cycles before wearing out, meaning you wouldn’t need to replace your device as often. The carbon nanotubes help the battery maintain its structure during repeated use. |

Future Growth and Impact

The partnership plans to dramatically increase production of these carbon nanotube pastes, aiming to make 25,000 tons annually by 2030. According to market research from QY Research, the global market for these materials is expected to reach $1.2 billion by 2030, growing at 13% each year from 2024.

Beyond batteries, these special carbon materials could eventually be used in many other products like stronger plastics, improved rubber, and even advanced electronics. As production scales up and costs come down, we might see these tiny tubes enabling lighter, stronger, and more efficient products in many areas of our lives.