New Ship Technology Can Capture 70% of Carbon Emissions

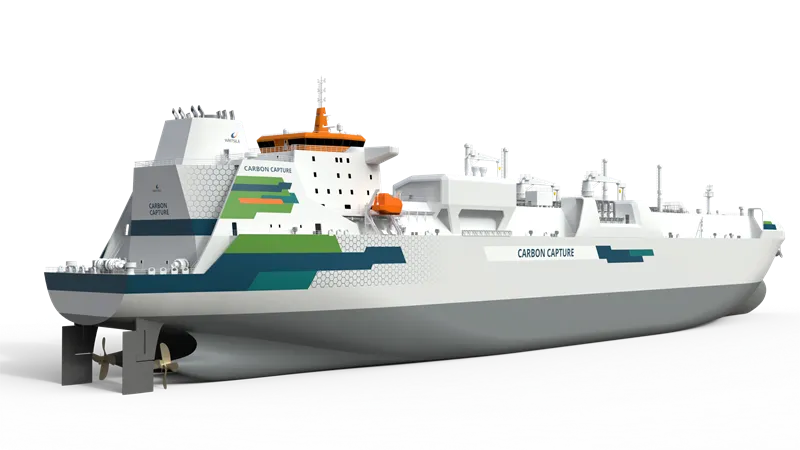

Have you ever wondered how massive ships could become less harmful to our planet? A groundbreaking new technology has just been tested that might change everything about how ships affect our environment. Technology company Wärtsilä has developed a special system that can catch and store the harmful carbon dioxide (CO2) that ships release into the air. According to a Wärtsilä Press Release, this new system can reduce ship CO2 emissions by up to 70%.

Understanding Ship Pollution and Why This Matters

Ships are essential for world trade, carrying goods across oceans, but they also create serious pollution problems. In 2022 alone, cargo ships produced 858 million tonnes of CO2, which contributes significantly to climate change. The shipping sector produces up to 3% of all human-caused CO2 emissions worldwide.

This new technology is particularly important because ships are extremely difficult to make environmentally friendly. Unlike cars that can easily switch to electric power, large ships need tremendous amounts of energy to cross oceans, making them hard to power with clean energy sources.

How the Carbon Capture System Works: A Simple Breakdown

Wärtsilä’s system works like a special filter that cleans the exhaust coming out of ship engines. It uses a five-stage process to capture, compress, and store the CO2 that would normally go into the air.

- Step 1: Pre-conditioning – The system first cleans and cools the hot, dirty exhaust gas. This works similar to how you might rinse something before washing it thoroughly, removing large particles that could cause problems later.

- Step 2: Absorption – A special liquid called an amine solvent is sprayed through the exhaust. This liquid acts like a magnet for CO2 molecules, attracting and capturing them while letting other gases pass through.

- Step 3: Desorption – The liquid now full of captured CO2 is heated, which makes it release the CO2 in a concentrated form. This is like boiling water to create steam, except it’s releasing pure CO2.

- Step 4: Liquefaction – The concentrated CO2 gas is compressed, dried, and cooled until it becomes a liquid. This makes it much smaller and easier to store, similar to how water takes up less space as a liquid than as steam.

- Step 5: Storage – The liquid CO2 is stored in special tanks on the ship until it reaches port, where it can be unloaded and potentially used for other purposes or stored permanently.

This system can process up to 50 tonnes of CO2 every day from ship engines, which is roughly equivalent to the daily emissions of thousands of cars. The Maritime Executive confirms these capabilities based on tests at sea and in Wärtsilä’s Norway plant.

Real-World Testing: The Clipper Eris Experience

The first full-scale test of this technology began in February 2025 on a ship called Clipper Eris, which sailed from Singapore. This ship is an ethylene carrier, which means it transports ethylene gas used to make plastics and other products.

According to Maritime Bell, the carbon capture system on Clipper Eris has successfully reduced emissions by 70% based on real-world data. Solvang ASA, the shipping company that owns Clipper Eris, reports that the system captures 70-80% of CO2 from both main and auxiliary engines.

| Test Results from Clipper Eris | Performance Details |

|---|---|

| CO2 Reduction Rate | 70-80% of all engine emissions captured, confirmed by multiple sources including Shipping Matters and New Atlas. This means that for every 10 tonnes of CO2 that would normally go into the atmosphere, about 7-8 tonnes are captured instead. |

| Daily Processing Capacity | Up to 50 tonnes of CO2 per day from heavy fuel oil engines. To understand this scale, it’s roughly equivalent to the amount of CO2 produced by driving an average car for 250,000 miles. |

The Cost and Benefits: Making Economic Sense

Using this technology costs between €50 to €70 (US$54 to $76) per tonne of captured CO2, according to the collected information. While this might sound expensive, it’s actually much cheaper than potential future fines of up to US$380 per tonne that ships might face for releasing carbon.

Håkan Agnevall, President and CEO of Wärtsilä, described the technology as a “game-changer for the maritime industry,” noting they are already seeing “huge interest in the market” for this solution. This enthusiasm suggests shipping companies see the economic benefits despite the initial costs.

However, the Global Centre for Maritime Decarbonisation’s COLOSSUS study found higher costs in some scenarios, estimating avoided carbon costs of $269 to $405 per tonne for 40% capture on medium-range tankers. This wide range of cost estimates shows that the economics may vary depending on the specific ship and implementation.

Challenges and Limitations to Overcome

Despite its promising results, this technology faces several important challenges that need to be addressed before widespread adoption. The Maritime Technologies Forum states that while onboard carbon capture is feasible, it requires significant vessel changes and increases fuel use.

- Safety Concerns – There are legitimate worries about crew safety, including potential exposure to hazardous chemicals used in the process, risks of suffocation if CO2 leaks occur, and explosion dangers from the pressurized tanks used to store the liquid CO2.

- Regulatory Framework – According to Ship & Bunker, the International Maritime Organization aims to finalize regulations for onboard carbon capture by 2028. Without clear rules, shipping companies might hesitate to invest in the technology.

- Infrastructure Needs – DNV (a maritime classification society) notes that the entire carbon capture, utilization, and storage value chain needs further development. This means ports need facilities to accept the captured CO2 and infrastructure to transport or use it.

- Energy Requirements – The system itself requires significant energy to operate, which partially offsets the environmental benefits by increasing fuel consumption.

Global Impact: What This Could Mean for Climate Goals

If widely adopted, this technology could potentially reduce global emissions by up to 700 million tonnes per year, making a significant contribution to fighting climate change. This would help the shipping industry move toward the International Maritime Organization’s goal of reaching net-zero emissions by 2050.

Edvin Endresen, CEO of Solvang ASA, emphasized this point, saying: “While the shipping sector continues to explore options for lessening its environmental impact, CCS provides a significant shortcut for achieving meaningful sustainability.”

Looking Ahead: What Comes Next

Wärtsilä plans to make this carbon capture technology commercially available in 2025. The system is designed to be modular, meaning it can be added to existing ships (retrofitted) or included in new ship designs.

For the technology to reach its full potential, several things need to happen: regulatory frameworks must be finalized, port infrastructure for handling captured CO2 needs development, and shipping companies will need financial incentives to adopt the technology.

As climate regulations become stricter worldwide, technologies like this may move from optional improvements to necessary investments for shipping companies wanting to avoid hefty fines and meet international requirements.

Conclusion: A Significant Step Forward

Wärtsilä’s carbon capture technology represents a major advancement in reducing maritime emissions, offering a practical solution that works with existing ship engines. While challenges remain, the successful testing on Clipper Eris demonstrates that significant emission reductions are achievable with current technology.

As the world continues searching for ways to combat climate change, this innovation shows how traditional industries can dramatically reduce their environmental impact without completely reinventing themselves. The question now is how quickly this technology can be scaled up and implemented across the global shipping fleet.