Have you noticed more electric buses on the roads lately? Two big companies just joined hands to make these buses even better. The Economic Times reports that JBM Electric Vehicles and Hitachi ZeroCarbon are now working together to improve how e-bus batteries work and last.

This new team-up will help collect real-time information from JBM’s electric buses to see how the batteries perform in different weather conditions. The announcement came on Wednesday, and the work will focus mainly in India and the Middle East.

Who Is Working Together

The partnership brings together experts from both companies who know a lot about electric vehicles and battery technology. Think of these people as the brains behind making e-buses run better and longer.

- JBM Electric Vehicles (part of JBM Auto Ltd)

- Hitachi ZeroCarbon

- Nishant Arya (Vice Chairman and Managing Director of JBM Auto Ltd)

- Ram Ramachander (CEO of Hitachi ZeroCarbon)

- Bharat Kaushal (Corporate Officer of Hitachi Ltd and Executive Chairman of Hitachi India)

What They Plan To Do

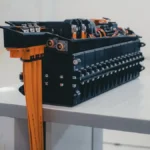

The main goal is to make e-bus batteries work better and last longer. Think of it like checking your phone’s battery health, but for big buses that run all day long. Hitachi’s special system will watch how the batteries perform when buses drive on different roads and in hot or cold weather.

- Use Hitachi’s ZeroCarbon BatteryManager to collect data

- Track how batteries perform in different weather

- Find better ways to charge the buses

- Learn how to make routes more efficient

- Help the batteries last longer

Why This Battery Work Matters

When e-bus batteries work better, everyone benefits. The buses can run longer without charging, which makes them more reliable for passengers. This work will help make electric buses cheaper to run over time – what experts call “total cost of ownership” – which means the money spent to buy, run, and maintain the buses.

Another important benefit is something called “residual value” – this means how much the bus is worth after years of use. Better batteries mean the buses stay valuable longer, like a phone that keeps a good battery even after two years.

JBM’s E-Bus Projects

JBM is not new to making electric buses. They can make up to 20,000 buses each year at their factory in the Delhi-NCR area. The company has already put many e-buses on roads across India and other countries.

- According to AutoCarPro, JBM Ecolife Mobility won a 5,500 crore contract to supply 1,021 electric buses under the PM e-Bus Sewa Scheme-2 across 19 cities in Gujarat, Maharashtra, and Haryana. JBM Auto has delivered about 2,000 electric buses across India, Europe, the Middle East, and Africa.

- According to EMobilityPlus, in March 2024, JBM launched 200 air-conditioned e-buses in Berhampur, Odisha, marking its entry into eastern India. Berhampur e-buses cover over 200 km per day and reduce carbon emissions.

- According to ETAuto, in March 2024, JBM Ecolife Mobility secured a contract to operate 1,390 electric buses under the PM-eBus Sewa Scheme, representing about 65% of the total electric buses in that initiative.

Special Features of Hitachi’s System

Hitachi’s ZeroCarbon BatteryManager is not just a simple tracking tool. Think of it like a smart doctor for bus batteries that checks health, gives warnings, and offers helpful advice. This system can do many useful things:

- According to Bus-News, it offers real-time battery health monitoring

- It provides proactive safety alerts

- It delivers smart battery management recommendations

- It includes integrated charge management

- It generates annual asset health reports to optimize electric bus fleet operations

Looking Ahead

This partnership between JBM and Hitachi could change how electric buses work in your city. As more cities switch to e-buses, the lessons from this team-up might help make public transport cleaner and more reliable. The next time you see an electric bus quietly moving through your neighborhood, you’ll know there’s some smart technology working behind the scenes to keep it running smoothly.