India’s Growing Steel Industry Creates Major Climate Challenge

India is planning something huge that will affect our planet’s health. The country wants to almost double its steel production by 2030, according to reports from EuroNews and Global Energy Monitor. This means going from making 200 million tonnes of steel each year to over 330 million tonnes. But this plan creates a big problem for fighting climate change.

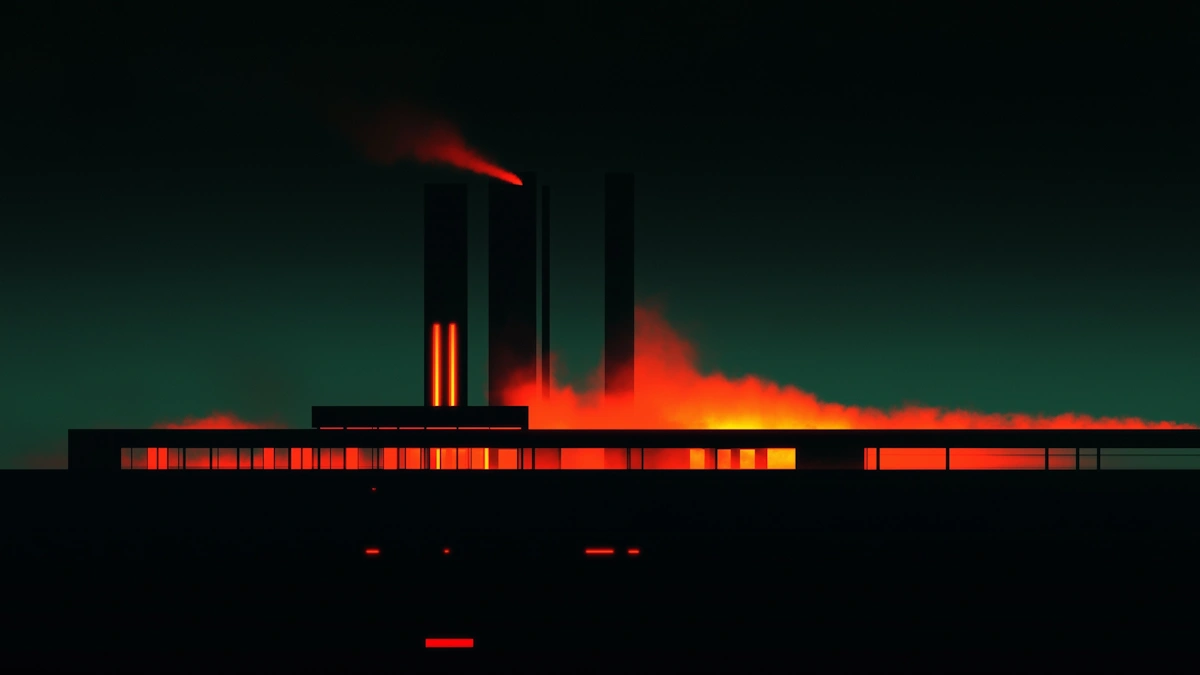

Making steel releases a lot of harmful gases into the air. For every tonne of steel produced in India, about 2.6 tonnes of carbon dioxide enter our atmosphere. This is like driving a car non-stop for months! Steel production already causes 12% of all greenhouse gases that India releases.

Why India’s Steel Plans Matter for Everyone

India is not just any steel producer – it’s the world’s second-largest. What happens in India affects everyone. More than 40% of all new steel plants being built or planned worldwide are in India. This makes the country’s choices extremely important.

“India is now the bellwether of global steel decarbonisation,” said Astrid Grigsby-Schulte, who tracks steel production at Global Energy Monitor. This means India’s decisions will show the direction for how the whole world makes steel in the future.

Why India Uses So Much Coal for Steel

- Cheap local coal: India has its own coal supplies that cost less than importing cleaner fuels like natural gas. This makes coal-based steelmaking more affordable in the short term, even though it creates more pollution.

- Young factories: Many of India’s steel plants are relatively new. Owners don’t want to close them early to build different types because that would waste their investment.

- Limited alternatives: India doesn’t have enough steel scrap or natural gas to completely switch to cleaner methods that other countries might use.

Cleaner Ways to Make Steel Explained Simply

There are several ways to make steel with less pollution. One important method uses electric furnaces instead of coal-burning ones. These electric furnaces can reduce pollution, especially if the electricity comes from clean sources like solar or wind power.

Another promising option is using hydrogen instead of coal. When hydrogen replaces coal in steelmaking, the only waste product is water, not carbon dioxide. India is starting small experiments with this technology through its National Green Hydrogen Mission.

Some factories are trying to capture the carbon they release before it enters the air. This method, called Carbon Capture Utilization and Storage (CCUS), could help existing coal-based plants reduce their impact. However, it’s expensive – costing $50-60 for each tonne of carbon dioxide captured.

Economic Risks of Not Changing

If India doesn’t make its steel production cleaner, it might face serious economic problems. Many countries are planning to charge extra taxes on imported goods that cause a lot of pollution when they’re made. These are called carbon border taxes.

Easwaran Narassimhan from Sustainable Futures Collaborative explains this challenge: “India may be better off tolerating some short-term pain of technological upgrading to make its steel cleaner for long-term competitiveness gain.”

Finding Balance Between Growth and Climate Goals

India faces a difficult balancing act. It wants to grow its economy and build more infrastructure, which requires lots of steel. At the same time, it has promised to reach net-zero carbon emissions by 2070.

The good news is that only about 8% of India’s planned new steel capacity has actually been built so far. This means there’s still time to change course and choose cleaner technologies. Will India take this opportunity to lead the world toward cleaner steel production? The answer will affect our planet’s future.