Canadian Company Turns Dangerous Asbestos Waste into Valuable Materials

Have you ever wondered if dangerous waste could become something useful and valuable? According to NewAtlas, a Canadian company “Exterra” is doing exactly that with old asbestos mining waste. Exterra has raised a big amount of money – CAD 20 million – to build a special facility that will change harmful asbestos mine leftovers into useful materials while also helping our planet.

What is This Company Doing?

Exterra is a decarbonization company from Canada that wants to solve two problems at once. They plan to clean up dangerous waste from old asbestos mines and turn it into materials we can use. Their leader, CEO Olivier Dufresne, is guiding this important work. The company will build what they call Hub I, which will be the world’s largest facility for processing asbestos mine tailings (the leftover material from mining).

“With this funding, we’ll accelerate commercializing our dual-pronged platform that valorizes over 90% of minerals from asbestos residues while creating one of the shortest nickel supply chains for EV electrification in North America,” explained CEO Olivier Dufresne about their plans. This means they’ll make useful materials and help build electric cars too.

The History of Asbestos in Canada

You might not know that Canada was once the world’s biggest exporter of asbestos, especially in the 1970s. The town where Exterra will build their facility was even named Asbestos until recently! Now it’s called Val-des-Sources. The Jeffrey Mine there closed in 2012 when people fully understood how dangerous asbestos is for our health.

- Location: Val-des-Sources (formerly called Asbestos) in Quebec, Canada

- Historical Significance: Canada was the largest asbestos exporter in the 1970s

- Current Challenge: About 800 million tons of leftover asbestos mine waste sits in Quebec, needing a solution

How the Technology Works

Exterra uses special methods they created themselves to change the dangerous asbestos waste into safe, useful materials. According to e360.yale.edu, they treat the asbestos mine tailings with a strong acid that breaks down the harmful fibers and helps them recover valuable materials.

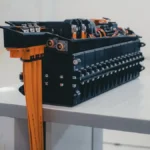

The company has two main technologies they’ve created, according to WCSecure. These are called LOW3 and ROC3:

- LOW3 (Low-carbon Oxide from Waste): This first process pulls out metal oxides (special mineral compounds) and other valuable materials from the mine waste

- ROC3 (Reactive Oxide to Carbonate): This second process takes those metal oxides and mixes them with CO2 (carbon dioxide) to make stable carbonate minerals that safely store the carbon

What makes this really special is how fast it works. According to Sustainablebiz, Exterra’s method turns CO2 into solid minerals in just four hours. This is amazing because nature would take about 10,000 years to do the same thing!

Carbon Capture: Cleaning the Air Too

One of the biggest benefits of Exterra’s work is that it helps fight climate change. Their process doesn’t just make useful materials – it also removes carbon dioxide from the air and locks it away safely in solid form.

| Project Stage | Timeline | CO2 Capture Amount | What This Means |

|---|---|---|---|

| Current Pilot | Now | 300 tonnes/year | Testing the process |

| Pre-Commercial Plant | 2025 | 3,000 tonnes/year | Growing the solution |

| Hub 1 Commercial Plant | 2026 | 500,000 tonnes/year | Same as taking 100,000 cars off the road |

According to CarbonCaptureMagazine, their test project is already capturing about 300 tonnes of carbon each year. But CarbonHerald reports that when Hub 1 is fully working in 2026, it will capture as much carbon as taking 100,000 gasoline cars off the road!

Why This Matters to Our Planet

This project is important for several big reasons:

- Safety Improvement: It removes dangerous asbestos waste that can cause serious health problems

- Resource Creation: It makes valuable materials like nickel that we need for electric cars

- Climate Help: It captures carbon dioxide that would otherwise warm our planet

- Waste Reduction: It finds a use for about 300,000 tons of waste each year

According to SenCanada, Exterra’s ROC3 technology is much better than other carbon capture methods because it doesn’t need high temperatures or huge equipment. It works at the surface level, making projects happen faster than methods that store carbon underground.

Looking Ahead: When Will This Happen?

Exterra plans to start building their main facility (Hub I) in 2027. They’re working step by step, starting with smaller test projects and growing bigger each year. If successful, they could eventually process up to 800 million tons of asbestos mine waste in Quebec.

This could be the first project in the world to make carbon-neutral minerals from mine waste on a big scale. The facility will run on clean, renewable energy, making the whole process better for our environment.

Final Thoughts: Turning Problems into Solutions

Imagine if more companies found ways to turn harmful waste into helpful products! Exterra shows that with clever thinking and new technology, yesterday’s dangerous leftovers can become tomorrow’s valuable resources. As you read about more environmental solutions like this, remember that solving old problems can sometimes create new opportunities that help everyone.