Revolutionary Batteries That Double as Car Parts Could Transform Electric Vehicles

Imagine if the parts of your car that hold it together could also store power. This is exactly what researchers at Chalmers University of Technology in Sweden are developing – batteries that work as both energy storage and structural support. According to TheBrighterSide, this breakthrough could make electric cars lighter, more efficient, and able to drive much farther on a single charge.

What Are Structural Batteries?

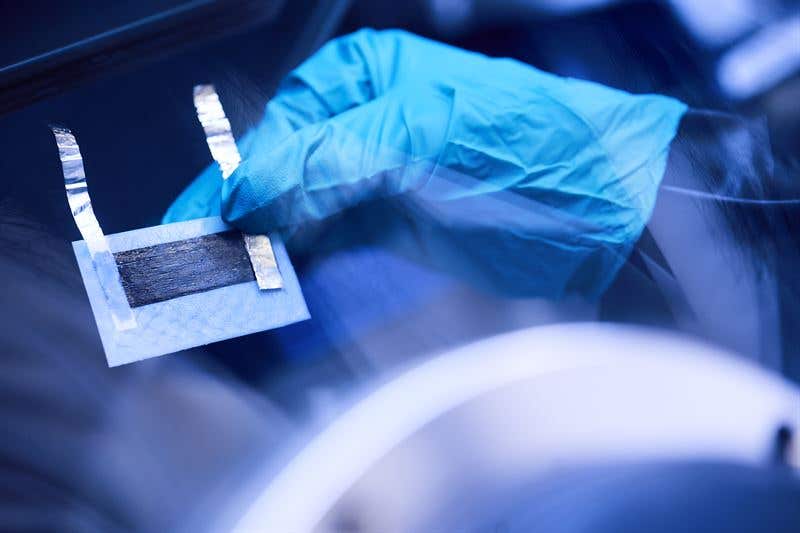

Structural batteries are special power sources that do two jobs at once – they store electricity while also helping hold a device together. “It’s like a human skeleton,” explains Richa Chaudhary, a researcher working on the project. “It carries loads but also performs other vital functions.”

The research team, led by Leif Asp, began this work in 2018. They use carbon fibers – thin, strong threads – that act as both the structure and the electricity-carrying parts of the battery. These special fibers are combined with materials like lithium iron phosphate to create power-storing components that can replace regular car parts.

How These Batteries Are Different

| Structural Batteries | Regular Batteries |

|---|---|

| Work as both power source and structural support – like having bones that store energy while supporting your body | Only store power – like carrying a separate water bottle instead of having water stored in your tissues |

| Use carbon fibers that do two jobs at once – providing strength and storing electricity | Have dedicated parts for strength and separate parts for storing electricity |

The current version of these batteries has reached what scientists call an energy density of 30 Wh/kg. This simply means how much power they can hold for their weight. They also have an elastic modulus of 70 GPa, which measures how stiff and strong they are – important for car parts.

Real-World Benefits

- Could reduce vehicle weight by up to 20% – like removing one person’s weight from a five-passenger car

- Might increase how far electric cars can drive by 70% – turning a 300-mile range into 510 miles

- Would create more sustainable transportation by using less materials and energy

Leif Asp emphasizes the importance of this work: “Investing in light and energy-efficient vehicles is a matter of course if we are to economize on energy and think about future generations.”

Challenges Still Ahead

Despite the exciting progress, several hurdles remain before these batteries appear in everyday cars:

- Engineers need to move from liquid to semi-solid materials inside the batteries for better power and safety

- The complex shapes needed for car parts make these batteries difficult and expensive to manufacture

- Once built into the car’s structure, these batteries would be challenging to replace if they wear out

The journey from laboratory to your garage will take time, but the potential benefits are enormous. These structural batteries represent a fundamental rethinking of how we build and power vehicles. Rather than carrying heavy battery packs, future cars might use their floors, doors, and frames to store energy – making electric transportation lighter, more efficient, and better for our planet.